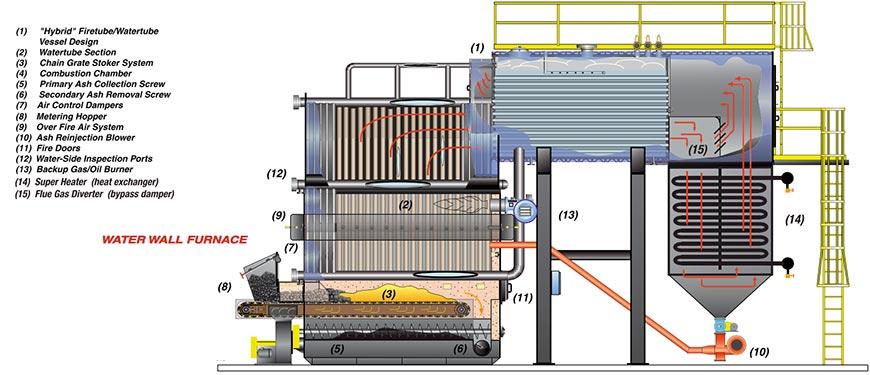

This system is designed by HBC to combine the best technologies from the “old school” of coal combustion and the latest advanced combustion control technologies. The new HBC chain grate-type stoker system permits either bituminous coal washed singles or smalls to be combusted in an efficient manner with the added advantage of automatic de-ashing. This combination is particularly suitable for industrial heating and process steam applications. The boiler vessel is a two pass hybrid design incorporating a water tubed boiler-type water membrane and a two-pass fire tube scotch marine vessel. This vessel’s advantages over standard water tube boilers include much larger steam disengagement area providing high quality steam, larger steam storage capability for quicker response to sudden steam demand and much larger thermal storage that provides fast demand response times and safer operation. This system also incorporates extended water wall membranes that extend down the gasification/combustion chambers side walls thereby greatly reducing refractory requirements which is essential when utilizing highly volatile solid fuels. The addition of a steam superheater allows this system to provide hotter steam (an additional +100º F) that can increase electrical cogeneration output over standard steam applications and specialized plant process applications.